Before applying epoxy to wood, it is important to seal the wood with a clear coat sealer. This will help to prevent the epoxy from soaking into the wood and creating a weak bond. It is also important to rough up the surface of the wood before applying the sealer, as this will help the sealer to adhere better.

If you’re working with wood, epoxy is a great way to seal it and protect it from moisture. But before you apply the epoxy, you need to make sure the wood is properly sealed. That’s where a good wood sealer comes in.

A good sealer will help keep the epoxy from seeping into the wood and will also provide an extra layer of protection against moisture. Sealers come in both water-based and oil-based formulas, so be sure to choose one that’s compatible with your epoxy. Once you’ve applied the sealer, let it dry completely before proceeding with the epoxy application.

DIY – Epoxy table – episode 3, how to seal wood for epoxy table

Should I Seal Wood before Epoxy Resin?

Most people choose to seal their wood before epoxy resin for two primary reasons:

1. To prevent the wood from warping; and

2. To create a barrier between the wood and the resin so that the resin does not soak into the wood (and potentially cause it to rot).

Sealing wood is particularly important if you are using a clear epoxy resin, as any imperfections in the wood will be visible once the resin is applied. You can use a number of different products to seal your wood, including polyurethane, shellac, or even just a simple layer of paint. Once your sealer is dry, you are ready to apply your epoxy resin.

Can I Seal Wood With Polyurethane before Epoxy?

It’s a common question we get here at the shop: can I seal wood with polyurethane before epoxy? And the answer is…maybe.

It depends on the project you’re working on and the look you’re going for.If you’re trying to create a smooth, glossy finish, then sealing the wood with polyurethane first will give you a head start. The polyurethane will fill in any imperfections in the wood and create a barrier against moisture, which will make it easier to get a flawless finish with your epoxy.

However, if you’re going for a more rustic look, sealing the wood first may not be necessary. Epoxy can adhere well to bare wood, so you may be able to skip this step altogether. Just keep in mind that any knots or irregularities in the surface of the wood will show through after epoxy is applied, so if you want a completely smooth finish, sealing first is probably your best bet.

How Do You Prepare Wood for Epoxy Pour?

When it comes to working with epoxy, preparation is key. If you want your epoxy pour to turn out flawlessly, you need to take the time to properly prepare your wood surface. In this blog post, we’ll show you how to do just that.

The first step is to sand the wood surface. You’ll want to use a coarse grit sandpaper (60-80 grit) and sand the entire surface until it’s smooth. Once you’re finished sanding, wipe away any dust with a damp cloth.

Next, apply a layer of primer to the wood surface. This will help the epoxy adhere better and create a smoother finish. Let the primer dry completely before moving on to the next step.

Now it’s time for the fun part – mixing up your epoxy! Follow the instructions on your chosen epoxy product and mix together equal parts resin and hardener. Once mixed, immediately begin pouring it onto your prepared wood surface.

Start in one corner and pour slowly, moving across the surface in a uniform manner. Be sure not to pour too thickly or else your epoxy will take forever to cure (dry). Also be careful not pool any excess epoxy around edges or corners – this can cause air bubbles which will ruin the final finish of your piece!

Once you’ve poured all of your epoxy, use a popsicle stick or other blunt object to lightly swirl around the wet mixture. This will help release any trapped air bubbles so they can rise to the top and pop.

How Do You Keep Epoxy from Seeping under Wood?

When working with epoxy, it’s important to be aware of how the material can seep under wood and cause problems. There are a few things you can do to keep this from happening:1. Use tape or another barrier around the edge of your wood.

This will help to create a seal and prevent epoxy from seeping in.

2. Make sure that the wood surface is completely clean before applying epoxy. Any dirt or debris will provide a pathway for the material to seep under the wood.

3. Apply epoxy in thin layers, allowing each layer to dry completely before adding more. This will help to prevent seeping by creating a stronger overall bond.

4. Use clamps or weights to hold the wood in place while the epoxy dries.

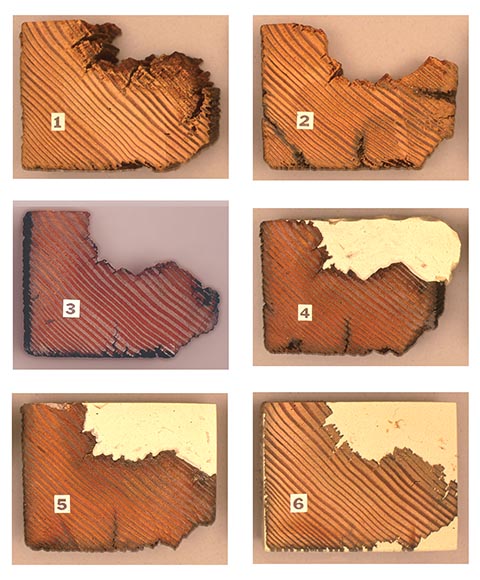

Credit: www.smithandcompany.org

Sanding Sealer before Epoxy

If you’re working with epoxy, it’s important to use a sanding sealer before you start. This will help to prevent the epoxy from seeping into the pores of the wood and creating a weak bond. A sanding sealer will also help to create a smooth surface for the epoxy to adhere to.

Conclusion

If you’re looking to protect your woodworking projects with a clear sealer before adding an epoxy topcoat, there are a few things you need to know. In this blog post, we’ll share the best wood sealers to use before epoxy, how to apply them, and what to look for in a quality product. We’ll also answer some common questions about sealing wood before epoxy.

By the end of this post, you’ll have all the information you need to choose the best sealer for your project!