To bypass an ECM motor, begin by turning off the power to the unit. Next, locate and disconnect any wires from the circuit board of the ECM motor. Then, use a jumper wire to bridge across pins 1 and 2 on the circuit board.

This will effectively bypass all control logic in the motor and allow it to run at its full speed regardless of external conditions. If you are running multiple ECM motors, make sure that none of them are connected so they can’t communicate with each other before jumping them out. Finally, turn on power to restart the system and check if everything is operating properly before restoring connections as needed.

- Step 1: Remove the power to the motor

- This should be done by shutting off the circuit breaker or unplugging any wiring connected to the motor

- Step 2: Inspect the ECM for any visible signs of damage such as cracks, chips or discoloration

- If there is damage then it will need to be replaced before continuing with bypassing process

- Step 3: Disconnect all wires from the ECM and unscrew any bolts holding it in place

- Carefully remove it from its mounting location and set aside for now

- Step 4: Locate a bridging wire that is compatible with your particular motor’s voltage rating (typically 120VAC)

- Connect one end of this wire to one terminal on your motor, and connect the other end of this wire to another terminal on your motor

- This will bypass both sides of your ECM completely and allow power directly through your motor without going through an electronic control module first

- Step 5 : Re-apply power to your system and test if everything runs properly while bypassing the ECM Motor successfully!

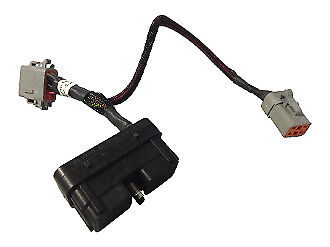

Credit: www.ebay.com

What Usually Fails on an Ecm Motor?

The ECM motor is known for its reliability, but there are some things that can go wrong. The most common failure points include:• Wiring connections: Poor connections and corroded wires can cause the motor to fail.

• Motor overloads: When too much current flows through the system, it can damage components or create an electrical fire hazard.

• Bearing wear: Over time, bearings in the motor will wear out and need to be replaced.Overall, these three issues are the primary culprits when it comes to ECM motor failure.

To ensure long-term dependability, regular maintenance checks should be performed on all motors in a facility.

How Do I Know If My Ecm Motor is Bad?

To determine if your ECM motor is bad, you should check for the following:– Inspect wiring and connections for signs of wear or damage.

– Check for power at the motor when it’s activated.

– Ensure that the motor runs smoothly without any jerking or grinding noises.

– Test current draw to identify any issues with voltage or amperage levels.If any of these checks indicate an issue, then it may be time to replace your ECM motor.

How to Control Ecm Motor Speed?

Controlling the speed of an ECM motor is essential for efficient operation. Here are some tips to ensure proper control:• Understand the components of a variable frequency drive (VFD) system, including power supplies, drives and motors.

• Use an AC inverter or DC controller to adjust voltage and current levels as needed.

• Monitor motor speed using feedback signals like tachometer inputs or encoder/resolver outputs.

• Implement velocity loop control strategies such as PI or PID controllers for optimal performance.

Finally, use high-quality components that are designed to handle the load and environmental conditions your application requires. With these tips in mind, you can ensure your ECM motor operates with ideal efficiency at all times!

What Tells an Ecm Motor to Ramp Up?

An Electronic Commutated Motor (ECM) motor is programmed to ramp up when it receives a signal from a thermostat or other controlling device. The following are the key components that tell an ECM motor to ramp up:

– Control Board: This component sends signals to the ECM fan motor to adjust speed based on temperature settings.

– Variable frequency drives: These electronic devices use external inputs, such as temperature and pressure sensors, to control output frequency of the AC power supply.

– Thermostats: Thermostats detect changes in air temperature within an environment and send signals for the ECM motor to respond accordingly.

By receiving these signals, the ECM can quickly adjust its speed and increase airflow depending on changing conditions inside of a space or building.

Fast Easy ECM FAN MOTOR Troubleshooting! ECM Blower Motors with Spade Terminals!

Ecm 3.0 Motor Troubleshooting

If you are having trouble with your ECM 3.0 motor, start by checking all of the electrical connections and testing for continuity. If there are no issues with the wiring or connections, then it may be necessary to open up the unit and inspect any components that could potentially be causing problems. Additionally, if the motor isn’t working correctly, consult a professional technician who is familiar with this type of motor in order to ensure that it is properly serviced and repaired.

How to Test Ecm Motor With Multimeter

Testing an ECM motor with a multimeter is relatively simple and can be done in just a few steps. First, set the multimeter to measure resistance by selecting the highest setting on the ohm scale. Next, disconnect all power sources from the motor so that it’s completely isolated.

Then, touch one of your meter probes to each of the two terminals on your ECM motor and record the reading you get. If it reads infinity or no continuity then there is something wrong with your motor and needs further investigation or replacement.

Bypass Control Board on Furnace

If you need to bypass the control board on your furnace, you’ll have to disconnect the wires from the board. To do this safely, make sure that power is turned off and then remove all of the screws holding in the access panel. This will allow you to get direct access to each individual wire connected to the control board.

Once they are disconnected, it’s simply a matter of re-connecting them in such a way as to bypass any control coming from your furnace’s main circuit board. Be sure that all connections are correct before reinstalling the access panel and restoring power – otherwise, it could lead to damage or even fire!

Bypass Furnace Control Board for Heat

A bypass furnace control board is a great option for homeowners looking to increase the efficiency of their heating system. Bypassing the control board can reduce energy costs by allowing you to regulate the temperature in your home more accurately. Additionally, it eliminates any potential issues with the existing control board, such as incorrect readings or malfunctioning components.

However, this process should only be done by a professional HVAC technician as improper installation could result in safety risks and damage to your furnace.

How to Bypass Blower Motor Relay in Car

If your car’s blower motor relay needs to be bypassed, you can do so by connecting the positive and negative wires from the battery directly to the blower motor. Make sure that when making this connection that all necessary safety precautions are taken, including wearing insulated gloves and ensuring no other wiring is in contact with these connections. Additionally, make sure to install an appropriately-sized fuse on both of the wires being used for the bypass so as to avoid any potential damage caused by a short circuit or power surge.

Ecm Motor Troubleshooting Pdf

If you are having trouble troubleshooting your ECM motor, then a good resource to have is an ECM Motor Troubleshooting PDF. This document provides detailed instructions and diagrams on how to diagnose and repair any issues related to the motor. It also includes helpful tips on maintenance, as well as recommended parts for replacement if needed.

Having an ECM Motor Troubleshooting PDF can be invaluable when it comes time to fix whatever issue you may have with your motor!

Ecm 2.3 Motor Programming

ECM 2.3 motor programming is a method of controlling an electronic motor control system that utilizes the latest in microprocessor and software technology to ensure efficient operation and precise control over speed, torque, position, temperature, and other motor parameters. This type of motor programming can be used in a wide range of applications including robotics, industrial automation systems, automotive engine controls, medical device controllers and more. The ECM 2.3 provides users with advanced features such as motion profiles for complex motion requirements as well as options for customizing how the controller operates based on user-defined parameters.

How to Bypass Blower Motor Resistor Silverado

If your Silverado’s blower motor resistor is not functioning properly, you can bypass it by removing the old one and installing a jumper wire. First, shut off the ignition and disconnect the negative battery cable. Then locate the blower motor resistor which is usually located near the blower motor under or behind the glove box.

Remove all wiring connectors and then remove two mounting screws to remove it from its housing. From here, connect a jumper wire between two of its terminals in order to bypass it and restore full power to your Silverado’s HVAC system.

Conclusion

Bypassing an ECM motor is a relatively simple process that can be accomplished with just a few tools and some basic knowledge of the workings of your vehicle. With the right information, you can easily bypass an ECM motor to get your car running again. However, it’s important to note that this should only be done as a last resort if other options have been exhausted, as there may be serious consequences for tampering with any part of your vehicle.

In conclusion, understanding how to bypass an ECM motor can save you time and money in some cases; however, it is always best practice to contact a professional mechanic before attempting any repairs yourself.