So you have two horizontal drain pipes that need to be joined together to create a longer run or connect to a new fixture. But you don’t know How to Connect Two Horizontal Drain Pipes, right?

The good news is the process is not that tough. You can easily connect horizontal drains with proper fitting materials and techniques for cutting, measuring, and securing the pipes together.

I will provide a step-by-step guide on connecting two horizontal drain pipes, including the necessary tools and materials needed and helpful tips to make the process go smoothly. Whether you’re a seasoned DIY enthusiast or a beginner, this guide will equip you with the knowledge and skills to complete your plumbing project successfully.

Here are the steps.

- Locate the drain pipes that you need to connect. If they are buried, you will need to excavate them.

- Cut both pipes so they are flush with each other.

- Apply a generous amount of pipe joint compound to both ends of the pipes.

- Slide a coupling over both ends of the pipes and tighten it in place with pipe wrenches.

Don’t worry, we will show you in detail.

Step-by-Step Guide: How to Connect Two Horizontal Drain Pipes

Let’s see everything in details.

Tools and Materials Needed

Before we get started, we need to gather some tools and materials. Here’s what we need:

- Two horizontal drain pipes

- Fittings (special connectors that join the pipes together)

- Hacksaw (a saw for cutting pipes)

- Measuring tape

- Sandpaper (to smooth the edges of the pipes after cutting)

Explanation of Each Item and Its Purpose

- The two horizontal drain pipes are the project’s main components, and they need to be the right size and type for the plumbing project.

- Fittings are essential in connecting the pipes, and couplings are used in this task. They work by sliding over the ends of the pipes and tightening them with a clamp to hold them in place.

- The hacksaw is used to cut the pipes to the correct length.

- Measuring tape is necessary to ensure that the pipes are cut to the correct length.

- Sandpaper is used to smooth the edges of the pipes after cutting. This ensures that the fittings fit snugly onto the pipes and prevent leaks.

Tips for Sourcing Materials for horizontal drain connections

When sourcing materials, it’s important to get them from a reputable supplier. Check reviews and ask for recommendations from friends or family members who have completed similar plumbing projects.

For finding the right tools, consider renting or borrowing if you don’t have them on hand. Look for a local hardware store or home improvement center with the necessary rent or sale tools. Remember to ask for advice on which tool is best for your specific plumbing project, and always follow safety precautions when using tools.

Step 1: Prepare the Pipes

- Turn off the water supply to the pipes you will be working on.

- Ensure the pipes are completely dry by wiping them with a towel or rag.

- This is an important safety measure to prevent accidental flooding or water damage.

Step 2: Measure and Cut the Pipes

- Use a measuring tape to determine the length of the two drain pipes that need to be connected. Measuring the pipes accurately is important to ensure they are the correct length and will fit together correctly.

- Once you have determined the correct length, use a pipe cutter or hacksaw to cut both drain pipes to the desired length. Ensure that the ends of the pipes are clean and free from debris.

Step 3: Apply PVC Primer and Cement

- Apply PVC primer to the outside of one of the pipes, ensuring that the primer covers the area where the PVC fittings will be attached. The primer helps prepare the pipe’s surface for the cement and ensures a strong bond.

- Apply PVC cement to the same area where the primer was applied, ensuring that the cement covers the same area. The cement bonds the pipe and fits together, creating a strong, permanent connection.

Step 4: Insert the First Fitting

Insert the first PVC fitting onto the primed and cemented end of the pipe. Ensure that the fitting is fully seated and aligned with the pipe. You can twist the fitting slightly as you insert it to help it slide on more easily.

Step 5: Apply Primer and Cement to the Inside of the Fitting

Apply PVC primer and cement to the inside of the fitting, ensuring that the cement covers the entire fitting circumference. This step helps to create a strong bond between the fitting and the second pipe.

Step 6: Insert the Second Pipe

Insert the second pipe into the fitting and ensure it is fully seated and aligned. You may need to twist the pipe slightly as you insert it to ensure a snug fit.

Step 7: Apply Primer and Cement to the Second Pipe

Apply PVC primer and cement to the outside of the second pipe and insert the second PVC fitting onto the primed and cemented end of the pipe. This helps to create a strong bond between the pipe and the fitting.

Step 8: Repeat Steps 5 and 6 for horizontal waste pipe connections

Repeat steps 5 and 6 to connect the second pipe to the second fitting. This process is similar to the first connection but in reverse.

Step 9: Allow the Cement to Dry

Allow the cement to dry according to the manufacturer’s instructions before running water through the pipes. This is typically a few hours but can vary depending on the temperature and humidity.

Step 10: Test the Connection

Test the connection by running water through the pipes to ensure that there are no leaks. If you notice any leaks or drips, turn off the water supply and reapply primer and cement to the affected area. Allow the cement to dry again before testing the connection.

Can a wye be installed horizontally?

Yes, a wye can be installed horizontally, but the orientation of the wye depends on the specific application and the direction of flow. A wye is a type of fitting used in plumbing, HVAC, and other piping systems to split the flow of fluid or gas into two or more directions.

In some cases, a horizontal installation of a wye may be more practical or necessary to accommodate space constraints or the direction of the flow. However, it’s important to ensure that the wye is installed correctly and that the flow direction is appropriate for the specific system.

It’s also important to note that the installation of a wye, or any other type of piping fitting, should be done according to local building codes and industry standards to ensure proper functionality and safety of the system.

How to do horizontal to horizontal drain connection wye

- Choose the appropriate wye fitting: Make sure to select a wye fitting that is designed for horizontal installations and is suitable for the type of fluid or gas that will flow through the piping system.

- Determine the direction of flow: The wye should be installed in the direction of the flow, with the inlet on one end and the two outlets on the sides.

- Cut the pipe: Cut the pipe to the appropriate length for the installation, leaving enough room for the wye fitting and any necessary couplings.

- Install the wye: Place the wye fitting into the cut pipe section, making sure that the inlet is aligned with the flow direction.

- Secure the wye: Use appropriate couplings and clamps to secure the wye in place and prevent leaks.

- Test the system: After the wye has been installed, test the system for leaks and proper functionality to ensure that the installation was successful.

It’s important to note that the specific steps for installing a wye horizontally may vary depending on the type of piping system, the size and material of the pipes, and other factors. It’s always best to consult with a professional plumber or piping system installer to ensure that the installation is done correctly and safely.

The #1 DWV Plumbing Mistake (and how to prevent it).

- Place a drain pipe fitting on each end of the two horizontal drain pipes

- Connect the two drain pipes together using the drain pipe fitting

- Secure the connection by tightening the drain pipe fitting

Tying into a Vertical Drain Line

Vertical drain lines are an essential part of any plumbing system. They allow water to drain from the home and into the sewer system. You can tie it into a vertical drain line in a few different ways.

The first way is to use a wye fitting. This fitting has two inlets and one outlet. The inlets are connected to the vertical drain line and the outlet to the horizontal drain line.

Another way to tie into a vertical drain line is by using a tee fitting. This fitting has one inlet and two outlets. The inlet is connected to the vertical drain line, and one of the outlets is connected to the horizontal drain line.

The other outlet can be used for another fixture, such as a sink or toilet. The last way to tie into a vertical drain line is by using an elbow fitting. This fitting has one inlet and one outlet at 90 degrees from each other.

How Do You Join Two Drain Pipes Together?

You can join two drain pipes together in a few different ways, depending on the type of pipe and the materials you are working with. If you use PVC pipe, you can connect the two pieces with a PVC coupling. To do this, simply apply some PVC cement to the inside of the coupling and then push it onto the end of one of the pipes.

Once it is in place, repeat this process with the other pipe to insert both ends into the coupling. Then give it a few minutes to set before moving on. If you are working with metal drain pipes, you will need to use a slip joint fitting to connect them.

This is because metal pipes cannot be glued like PVC pipes can. To install a slip joint fitting, first wrap some plumber’s tape around the threads of one of the pipes. This will help create a seal so that water does not leak out when you connect the two pieces.

Then screw on the slip joint nut until it is tight against the pipe. Repeat this process with the other pipe and then screw on another nut until both pipes are securely connected.

How Should Horizontal to Horizontal Branches Be Connected in the Drainage System?

There are a few ways to connect horizontally to horizontal branches in the drainage system. One way is to use a wye fitting. This Y-shaped fitting allows two pipes to be connected at an angle.

Another way is to use a tee fitting. This T-shaped fitting allows one pipe to be connected to another pipe at right angles. The last way is to use an elbow fitting.

This L-shaped fitting allows one pipe to be connected to another pipe at an angle.

Can Drain Pipes Run Horizontal?

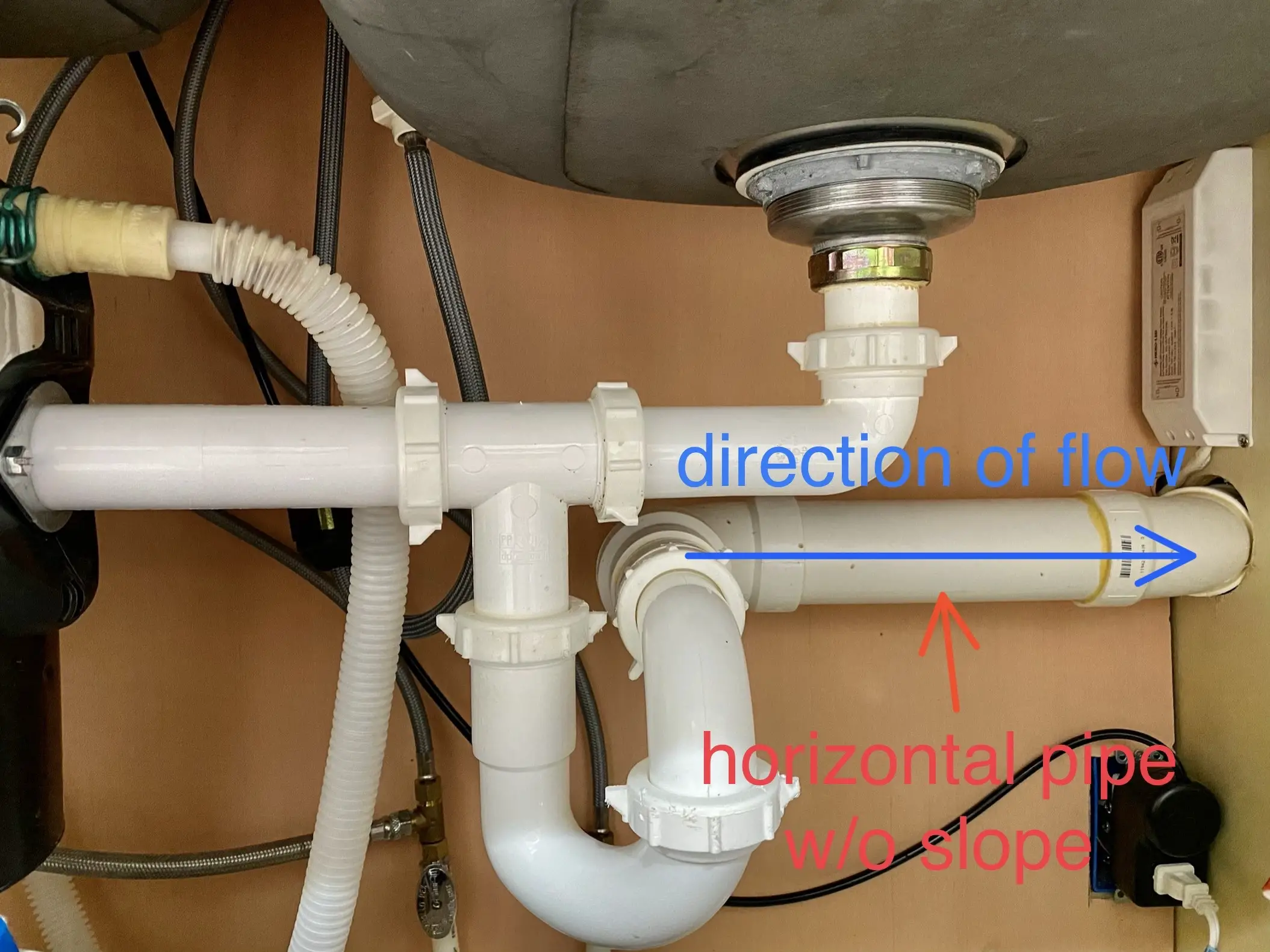

Can drain pipes run horizontally? YES, but there are a few caveats. First, your drain pipe must be sloped correctly so that water flows downhill and does not pool in the line.

Second, you need to have enough “drop” or height difference between the start and end of the horizontal run so that water drains properly. Third, horizontal runs should be as short as possible to prevent clogs.

Can a Double Wye Be Installed Horizontally?

Yes, a double wye can be installed horizontally. The main advantage of a horizontal installation is that it eliminates the need for special supports or structures to maintain the vertical orientation of the pipes. This can save time and money during installation.

In addition, horizontal installations are often used when space is limited, such as in crawlspaces or attics.

Conclusion

If you need to connect two horizontal drain pipes, there are a few things you’ll need to do. First, make sure that the pipes are the same diameter. If they’re not, you’ll either need to get an adapter or replace one of the pipes.

Second, clean the pipes’ ends so that no debris is blocking the connection. Once the ends are clean, apply a generous amount of plumber’s putty around one of the pipe connections. Then, push the two pipes together and twist them until they’re tight.

Finally, use a hacksaw to trim off any excess pipe so everything looks neat and tidy. Now you know How to Connect Two Horizontal Drain Pipes.